Unparalleled Expertise in Process Safety and Dust Explosion Testing:

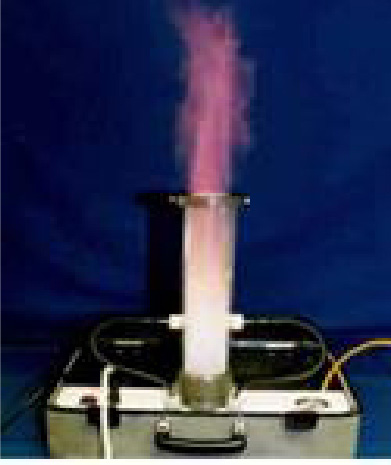

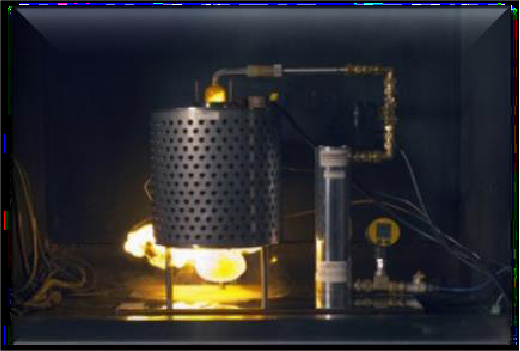

State of the art Laboratory Equipped with Advanced and Modern instruments with cutting edge technologies.

Aragen Life Sciences places an unwavering emphasis on safety, wholeheartedly embracing the revolutionary concept of ‘Safety by Design’ throughout its Chemical Development Solutions (CDS) and Custom Manufacturing Solutions (CMS) business model. This paramount concept is meticulously implemented at every stage, from conception and development to commercial manufacturing, to seamlessly cater to the exacting demands of our esteemed global clientele. To ensure this commitment, we have established a cutting-edge Process Safety Lab at our Hyderabad, Nacharam campus, epitomizing our dedication to unparalleled safety standards.

The crucial mission of a Process Safety Lab is to meticulously design and carry out process safety studies to gain an in-depth understanding and assessment of the potential hazards inherent in the processes developed for CDS and CMS. The insights gleaned from these studies act as a compass to steer the lab towards developing robust design and engineering controls, as well as a comprehensive risk mitigation plan that dramatically reduces the risk of runaway reactions, thus guaranteeing inherently safer processes that can be scaled up for commercial use.

The Process Safety Laboratory (PSL) group shoulders the critical responsibility of comprehending and mitigating the thermal hazards entwined with reagents, chemicals, and reactions at hand. Their unwavering dedication revolves around the relentless pursuit of minimizing risks associated with handling hazardous chemicals, waste streams, and the execution of perilous reactions. Neglecting the comprehension of chemical hazards harbours the potential to subject these reagents and/or mixtures to treacherous conditions, temperatures, and/or mechanical stress, thus inciting precarious situations like fires, deflagrations, and explosions. Such catastrophic events can trigger significant material loss, impede progress, disrupt supply chains, inflict injuries, and even claim lives. The PSL group’s commitment is an indispensable shield against these grave perils.

The group has designed range of tests to detect chemically unstable intermediates and reaction mixtures, guaranteeing that the intended operating conditions establish an ample safety buffer against the initiation of disastrous and potentially fatal thermal decompositions. Our highly proficient scientific personnel possess exceptional expertise in evaluating thermal and reaction hazards, guaranteeing the utmost safety of both laboratory personnel handling these materials and plant operators carrying out the procedures.

The lab classifies the hazards in the process with respect to chemicals, process equipment and environment. It then provides proper mitigation solutions by modifying the process and the outcome of the process safety lab data is predominantly used as a basic initial PSI during PHA/HAZOP studies of the respective molecules. The evaluated processes are classified based on the stoessels criticality classification and for gas generating reactions, adequate engineering, administrative and procedural controls are implemented during scale-up activity on the manufacturing floor.