Unparalleled Efficiency and Precision in HPAPI Development and Manufacturing.

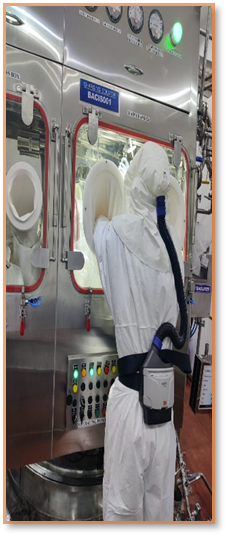

At Aragen, we combine our extensive experience and expertise to provide a comprehensive and streamlined process for both HPAPI development and manufacturing, ensuring skilled handling of all aspects of the product life cycle. Our state-of-the-art HPAPI manufacturing facilities offer you an exceptional experience, setting a new standard for quality and efficiency in the industry.